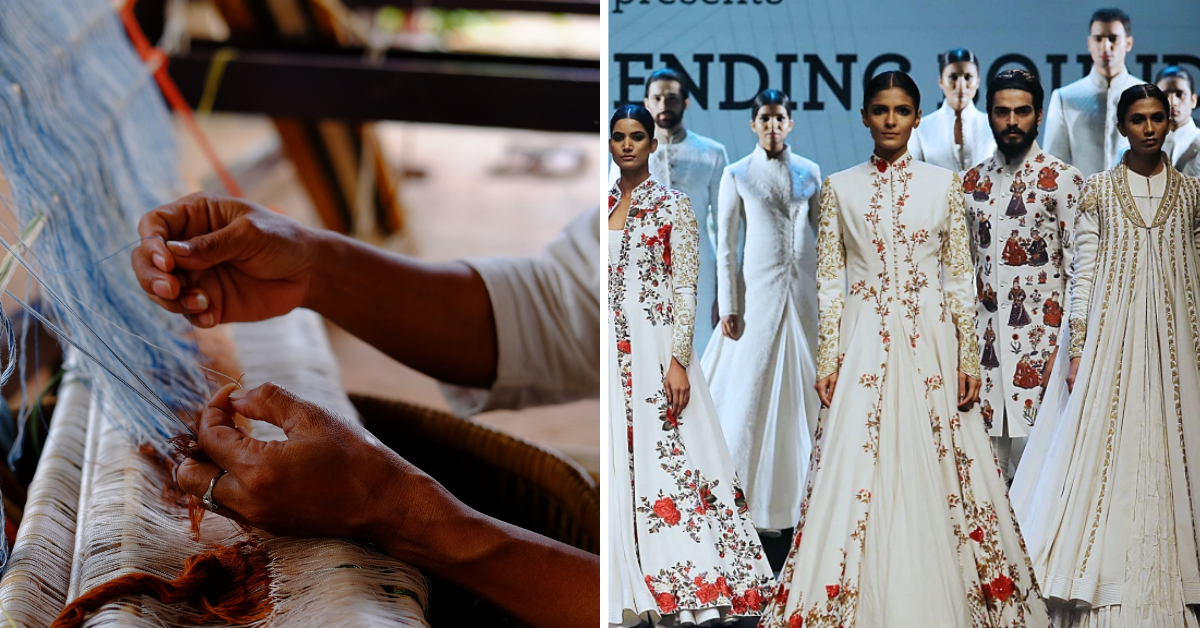

On a crisp winter night in New Delhi, the runway lights dim. A mannequin strides out in a sharply tailor-made, resin-coated khadi (handspun, handwoven material) jacket, its earthy tone lifted by advantageous seam work. Diplomats, designers and younger influencers lean in. A material born within the freedom wrestle holds the room.

Hundreds of kilometres away, in a village in Gujarat, an aged weaver bends over her charkha (spinning wheel). Cotton twists into yarn below practised palms. The wheel creaks, the air smells of uncooked fibre, and a neat stack of thread grows.

A single thread hyperlinks these rooms. It carries reminiscence, dignity and work. Campaigns and style councils have introduced khadi again into the sunshine, and designers now check its edges on India’s largest phases. World audiences are being attentive to this craft-rich, low-impact material. To know why this material nonetheless strikes a room, it helps to return to the place its thread first gathered energy.

Spinning a nation awake

In village courtyards, evenings ended with the gentle whirr of the charkha. From that rhythm got here khadi, rooted in khaddar (coarse handspun material) that many households knew by contact.

Within the early 1900s, the decision of Swadeshi (self-reliance) turned this home craft into citizen motion. Folks selected native material. The wheel moved from verandahs to public squares and got here to face for dignity, thrift and shared goal.

M Okay Gandhi positioned spinning on the coronary heart of every day life. He urged folks to spend a part of every day on the wheel, seeing it as work that would help households, strengthen communities, and instil self-respect and self-discipline.

Organisation adopted feeling. In 1925, the All India Spinners’ Affiliation was fashioned to help spinners and weavers, stabilise provide and hold incomes in rural palms. A family talent grew to become a nationwide programme of labor and satisfaction.

The image travelled onto the nation’s colors. In 1921, a proposed flag carried a spinning wheel at its centre. On 15 August 1947, the Ashoka Chakra changed the charkha on the nationwide flag, and the hyperlink between material, citizenship and self-reliance had already taken root.

Style weeks meet village yarn

At a metropolis khadi retailer, a pupil lifts a slubby cotton jacket to the sunshine. Throughout city, a small unit presses shirts for a design-school pop-up. The identical handspun material now strikes by way of becoming rooms, studio racks and runway rehearsals.

After Independence, speedy industrialisation, city migration and the unfold of synthetics shifted wardrobes and undercut every day use of khadi. To regular livelihoods, the Khadi and Village Industries Fee was arrange in 1957, changing an earlier nationwide board. Credit score adopted in 1977 by way of the Curiosity Subsidy Eligibility Certificates scheme, which gave registered items financial institution working capital at 4 per cent, with the Fee bearing the distinction.

Worth help developed with markets. A protracted-running gross sales rebate later grew to become Market Growth Help in 2010, then Modified MDA. In 2021, the coverage shifted to MDA on manufacturing so {that a} bigger share flowed on to spinners and weavers for high quality work.

Campaigns reframed the story for youthful patrons below Khadi for Nation, Khadi for Style, with Khadi Mahotsav (Khadi competition) metropolis activations and Khadi India shows at Lakmé Style Week x FDCI.

Retail gathered tempo. Khadi product gross sales rose steadily from about Rs 2,000 crore in 2016–17 to over Rs 3,200 crore in 2018–19. Regardless of latest shocks, resilience confirmed, with khadi material gross sales crossing Rs 5,000 crore by 2021–22 and persevering with to develop in 2022–23.

Why khadi speaks to in the present day’s India

On a sticky summer season commute, a younger skilled reaches for a handspun shirt. The weave lets air by way of, gentle on heat-tired pores and skin. That instinctive attain explains why many patrons are returning to khadi.

Sustainability leads the listing. Handspun and handwoven imply decrease power use and fewer power-heavy processes. Every metre carries extra human labour than machine time, supporting rural livelihoods and maintaining worth nearer to artisan properties.

Consolation seals the selection. Cotton khadi breathes, absorbs moisture and feels cool in summer season but comfy in milder winters. In tropical climate, airflow and softness matter as a lot because the reduce. The material settles to the physique and eases with put on, which is why a favorite shirt usually feels higher with time.

Provenance provides satisfaction. Buyers who care about traceable making, pure dyes and small-batch craft discover these cues in khadi. Many labels now share maker tales, dye notes and care directions that honour the folks behind the material, and superstar wardrobes and high-profile journal spreads have amplified the shift towards craft with credibility.

“It’s natural, breathable and timeless,” says style journalist Manish Mishra. He provides that in the present day’s style values make investing in khadi a transparent, eco-conscious selection.

Runway experiments in khadi

Backstage at a style week finale, sample cutters clean a resin-slick jacket whereas a stylist checks a handspun skirt. When the lights rise, khadi steps out with new confidence, formed by designers who research fibre, match, end and historical past.

“Within the palms of visionary designers, khadi has damaged free from its old school picture,” says style journalist Manish Mishra. He factors to Rajesh Pratap Singh’s experiments and notes that new blends now sit comfortably in bridal and ceremonial put on. Mishra provides that Indian designers have reimagined khadi throughout silhouettes, from anti-fit tunics and roomy jumpsuits to structured kaftans and shorts, with light-weight blends that really feel seasonless and trend-neutral.

On the runway, Rajesh Pratap Singh’s Lakmé Style Week x FDCI present drew headlines for resin-coated khadi jackets with suture seams and stainless-steel components — a gathering of engineered construction and handspun texture that caught the sunshine and held the road.

Designers akin to Rajesh Pratap Singh and Abraham & Thakore have expanded the vocabulary of khadi for city wardrobes, whereas labels like 11.11 construct collections round handspun material, pure dyes and small-batch making.

What the subsequent decade can spin

In a dye room scented with indigo and myrobalan, a younger designer lifts handspun cotton to the sunshine whereas a weaver checks the deal with. This shared bench of craft and design is the place khadi finds its subsequent chapter.

The curiosity is actual, and Mishra sees continued innovation that retains engineered finishes and metallic components with out dropping the handspun core, however the pathway must really feel viable.

Expert palms are ageing, and fewer younger folks enter full-time handloom work. Discipline surveys flag low, uneven earnings and a thinner pipeline of spinners, dyers and weavers. Beneath the SFURTI scheme (Scheme of Fund for Regeneration of Conventional Industries), conventional producers, together with khadi items, acquire widespread services, upgraded instruments, design inputs and market linkages so orders really feel regular, not seasonal.

Worth is a hurdle. Khadi is labour-intensive, so unit prices sit above many mill-made materials. Market research ready for the Khadi and Village Industries Fee level to stronger product growth, high quality methods and constant branding because the bridge to premium patrons who pays truthful margins.

Belief sits on the centre. The Khadi Mark Laws, 2013 require accredited labs to check material earlier than a Khadi Mark tag goes on, confirming material that’s handspun and handwoven from pure fibre. Clear provenance protects artisan worth and helps labels inform trustworthy product tales.

Attain grows with a click on. The Khadi India e-portal, launched in 2020, gives a nationwide shopfront, whereas metropolis shops and pop-ups add try-ons and match assist. As social commerce expands, small producers meet patrons straight, share care guides and study which silhouettes work.

Requirements hold the promise. Constant testing and ending let khadi meet premium and export bars. For the wearer, meaning dependable match, colourfast pure dyes and material that holds its form after wash and put on.

Design pulls the material ahead, and worldwide exhibitions, fair-trade pathways and abroad collaborations can place khadi alongside heritage icons like Scottish tweed or Japanese denim.

Pure dye analysis, blends with silk, wool or linen, and modern finishes present how handspun texture can sit with modern construction. Studios that work intently with artisan companions form silhouettes that really feel fashionable whereas maintaining the soul of the weave.

By latest shocks, the sector has proven resilience. Official updates monitor khadi and village-industry gross sales rising on stronger retail and product range. Pleasure is rising too amongst younger patrons who search out homegrown Indian labels. “Khadi in the present day is of the second and impossibly related,” says Mishra.

Why this handspun story lives on

Again on the New Delhi runway, the present closes. A flowing khadi robe in gentle ivory strikes below the lights, paired with handcrafted silver jewelry. The mannequin pauses. Cameras click on.

From spinning wheels to international catwalks, khadi has come full circle. It stands towards environmental injury, sameness and throwaway style. It carries satisfaction for weavers in small villages and for designers in busy studios.

In a world of marks, metrics and mass manufacturing, khadi gives one thing slower, richer and human. Worn as a jacket in Milan, a draped sari in Mumbai or a tunic in London, it stays what it has at all times been: a cloth with intent.

The lights dim once more, and someplace a wheel begins to show.